Step and Direction

STEP and DIRECTION Microstepping Drives

LAM Technologies

manufacturers a wide range of bipolar stepper motor drives, pulse train

controlled, with the traditional STEP and DIRECTION signals.

We offer drives designed to be mounted on DIN rail (DS10 series), open versions for

panel mounting (OS10 series),

very compact versions for wall fixing (LS10 series) and finally modules for

PCB mounting (USD series).

The fractionation step reaches 25600 steps per revolution and the

maximum input frequency exceeds 300KHz.

The power range is extraordinarily wide and includes models with supply

voltage from 18Vdc up to 240Vdc and current from 0.3Arms up to 10Arms

(corresponding to 14Apk or 14Imax). Within the same family the various models

share the same electrical connections and mechanical fasteners and this makes

easy and quick the migrations upwards or downwards of one's own application.

Many models are supplied also with the AC input (alternating current) which,

thanks to the integrated power supply, can be directly connected to the

transformer.

The high performance, the compact size, the availability from stock and the

low cost have for years determined the success of our microstepping drives,

controllable with STEP and DIRECTION signals, which are successfully used in

applications including pantographs CNC, labelling, plasma and laser cutting,

cartesian robots, solar chasers, etc.

Products

• DS10 series

• AC supply

• LS10 series

• AC supply

• OS10 series

• AC supply

• OS1041A

• USD series

MORE DETAIL

LAM Technologies offers a

complete range of microstepping drives directly programmable by the user.

The extraordinary flexibility of the product derives from the combination of powerful processing features and of a complete set of I/O, which also includes high-speed counters and analog input and outputs.

The application development cycle takes place inside the free UDP Commander software provided in support of the product which assists the customer during every step, from the programming to the application debug.

The test and debug tools are at the cutting edge and allow for example to insert breakpoints, advance an instruction at a time, view in real time the contents of registers and variables, etc.

The possibilities of using the programmable drives are nearly unlimited and often allow to realize applications without the need of external controllers.

• DS30 series

• DS3041

• DS3044

• DS3048

• DS3073

• DS3076

• DS3078

• DS3084

• DS3087

• DS3098

• AC supply

• DS3041A

• DS3044A

• DS3048A

• DS3073A

• DS3076A

• DS3078A

• DS3084A

• DS3087A

MORE DETAIL

PROGAMMABLE

Programmable Stepper Motor Drive with Digital and Analogue I/O |

| CONTACT US |

The extraordinary flexibility of the product derives from the combination of powerful processing features and of a complete set of I/O, which also includes high-speed counters and analog input and outputs.

The application development cycle takes place inside the free UDP Commander software provided in support of the product which assists the customer during every step, from the programming to the application debug.

The test and debug tools are at the cutting edge and allow for example to insert breakpoints, advance an instruction at a time, view in real time the contents of registers and variables, etc.

The possibilities of using the programmable drives are nearly unlimited and often allow to realize applications without the need of external controllers.

• DS30 series

• DS3041

• DS3044

• DS3048

• DS3073

• DS3076

• DS3078

• DS3084

• DS3087

• DS3098

• AC supply

• DS3041A

• DS3044A

• DS3048A

• DS3073A

• DS3076A

• DS3078A

• DS3084A

• DS3087A

MORE DETAIL

WITH FIELDBUS

User-programmable Microstepping Drives with Fieldbus, digital and analogue I/O

|

| CONTACT US |

The programmable step motor

driver with Fieldbus allow to easily manage multiple axis using one only

connection to the master control device.

The applications with great number of motors take huge advantages from the

use of fieldbus as it reduces wiring with economic benefits and realibility.

This technology also allows to place the drives close to the motors reducing the

space needed in the cabinet.

Some products are also able to execute an internal program and this makes them ideal to realize applications with distributed intelligence. The programmability of the drive is also useful to reduce the traffic of messages on the fieldbus and locally manage the operations in real time, such as stopping or starting of a movement in correspondence with a signal coming from a photocell or the update of the rotation speed according to an analog external quantity.

The range of Fieldbus drives also includes models with USB interface ideal to realize the PC-based applications. The drivers supplied with the product allow to use it both in Windows (32bit or 64bit) and Linux platforms.

Some products are also able to execute an internal program and this makes them ideal to realize applications with distributed intelligence. The programmability of the drive is also useful to reduce the traffic of messages on the fieldbus and locally manage the operations in real time, such as stopping or starting of a movement in correspondence with a signal coming from a photocell or the update of the rotation speed according to an analog external quantity.

The range of Fieldbus drives also includes models with USB interface ideal to realize the PC-based applications. The drivers supplied with the product allow to use it both in Windows (32bit or 64bit) and Linux platforms.

• DS5x series

• DS50 series

• AC supply

• DS5041A

• DS52 series

• DS5241

• AC supply

• DS54 series

• AC supply

• DS5441A

PCB MOUNTING

Microstepping Drives suitable for mounting on printed circuit board (PCB)

|

| CONTACT US |

Stepper motor driver conceived for PCB mounting represent an interesting opportunity for those who need to integrate multiple drives on a single board or want to combine together the control and the power.

The designer finally has a small size drive, that can integrate with his own electronics to make the final product compact, economical and exclusive.

LAM Technologies is the pioneer of this technology, having sold the first drive for stepper motors to be mounted on PCB in 1995.

• USD series

• USD10361

• USD20361

• USD10362

• USD20362

• USD10606

• USD20606

• USD50361

• USD60361

• USD50362

• USD60362

• USD50606

• USD60606

MORE DETAIL

Three

different sizes of NEMA17 stepper motors able to provide holding torque

of more than 0.5Nm (71oz-In).

Upon request it is possible to realize versions with double shaft or with a different wiring (i.e. with a different phase current).

A wide range of stepper motors available from stock characterized by high torque, compact size and competitive price. LAM Technologies offers high quality

• M1173020

• M1173021

• M1173030

• M1173031

• M1173040

• M1173041

MORE DETAIL

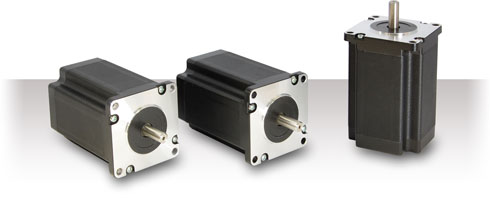

NEMA23

stepper motors in seven different power sizes with torque up to 3Nm

(425oz-In) always maintaining the flange in standard NEMA23.

Some models are offered with two different wirings to best fit in the application.

The motor shaft can be supplied with a diameter of 6,35mm (0,250In) or 8mm (0,315In) with flattening (recommended for motors with torque over 1,5Nm 213In).

The models M1233070 and M1233071 supply the highest torque amongst the motors with NEMA23 flange available on the market.

Family Overview

A wide range of stepper motors available from stock characterized by high torque, compact size and competitive price. LAM Technologies offers high quality:-

• M1233011

• M1233012

• M1233021

• M1233022

• M1233031

• M1233032

• M1233041

• M1233051

• M1233061

• M1233062

• M1233064

• M1233070

• M1233071

STEPPER MOTOR

|

| CONTACT US |

Upon request it is possible to realize versions with double shaft or with a different wiring (i.e. with a different phase current).

Family Overview

A wide range of stepper motors available from stock characterized by high torque, compact size and competitive price. LAM Technologies offers high quality

NEMA 17 Stepper Motor 42.3x42.3mm (1.67x1.67in) holding torque up to 0.5Nm (71oz-in)

NEMA 17• M1173020

• M1173021

• M1173030

• M1173031

• M1173040

• M1173041

MORE DETAIL

|

| CONTACT US |

Some models are offered with two different wirings to best fit in the application.

The motor shaft can be supplied with a diameter of 6,35mm (0,250In) or 8mm (0,315In) with flattening (recommended for motors with torque over 1,5Nm 213In).

The models M1233070 and M1233071 supply the highest torque amongst the motors with NEMA23 flange available on the market.

Family Overview

A wide range of stepper motors available from stock characterized by high torque, compact size and competitive price. LAM Technologies offers high quality:-

NEMA 23 Stepper Motor 56.4x56.4mm (2.22x2.22in) holding torque up to 3Nm (425oz-in)

NEMA 23• M1233011

• M1233012

• M1233021

• M1233022

• M1233031

• M1233032

• M1233041

• M1233051

• M1233061

• M1233062

• M1233064

• M1233070

• M1233071

|

| CONTACT US |

A series of

stepper motors with flange 60mmx60mm (also known as NEMA24), slightly larger

than the most common NEMA23.

The larger internal rotor allows to improve the performance of the

application when the load is highly inertial, as it improves the inertia

relation between the motor and the load itself.

Different windings are available for an optimal use of the motor at different speeds.

The model M1243044 at low phase inductance is particularly suitable when the drive is supplied at 24Vdc.

Family Overview

A wide range of stepper motors available from stock characterized by high torque, compact size and competitive price.

Different windings are available for an optimal use of the motor at different speeds.

The model M1243044 at low phase inductance is particularly suitable when the drive is supplied at 24Vdc.

Family Overview

A wide range of stepper motors available from stock characterized by high torque, compact size and competitive price.

NEMA 24

|

| CONTACT US |

The family of

NEMA34 stepper motors spread over six different stator lengths.

The maximum torque exceeds 12Nm (1416oz-In) placing this series of stepper

motors among the best performing commercially available.

All the motors have 8 wires and can be used both in bipolar and unipolar mode.

When the motors are used in bipolar mode (recommended to obtain the best performance) it is possible to choose between a series type connection, to limit the phase current, or parallel type, for applications exploiting the motors at high speeds.

The 14mm shaft diameter ensures stability in applications with belt transmission. Upon request the motor can be realized with 12mm shaft with key, with double shaft, etc.

All the motors have 8 wires and can be used both in bipolar and unipolar mode.

When the motors are used in bipolar mode (recommended to obtain the best performance) it is possible to choose between a series type connection, to limit the phase current, or parallel type, for applications exploiting the motors at high speeds.

The 14mm shaft diameter ensures stability in applications with belt transmission. Upon request the motor can be realized with 12mm shaft with key, with double shaft, etc.

NEMA 34

|

| CONTACT US |

With a static

torque up to 21Nm (2974oz-In) the NEMA42 stepper motors are used

successfully in the most demanding applications.

Supplied with 19mm diameter shaft and key, they can be mechanically and

electrically customized.

The windings have 8 wires and can therefore be used with unipolar type drives. When used in bipolar mode (recommended) it is possible to choose between a series type connection, to limit the phase current, or a parallel type, for applications exploiting the motors at high speeds.

The windings have 8 wires and can therefore be used with unipolar type drives. When used in bipolar mode (recommended) it is possible to choose between a series type connection, to limit the phase current, or a parallel type, for applications exploiting the motors at high speeds.